Sustainability is a huge buzzword in every U.S. industry, especially animal agriculture. Being able to call a product or a practice “sustainable” is practically like having a “get out of jail free” card in Monopoly. Great strides have been taken in recent years to prove, not just by common sense but through science, that the beef industry is sustainable.

A key element to beef’s validity as a sustainable product comes into play after the animal has been harvested. Given that only half of what a beef carcass yields is considered consumable in the U.S., beef production doesn’t sound very efficient, but utilizing the rest of that beef carcass – classified as beef byproducts – is an important part of what keeps the beef industry so sustainable. However, since the majority of U.S. beef producers stay focused on producing a healthy, high-quality animal, what happens after an animal arrives at the packing plant has remained mostly a mystery.

At the Cattlemen’s College sessions preceding the 2021 National Cattlemen’s Beef Association (NCBA) national convention and trade show in Nashville, Tennessee, Daniel Schaefer, vice president of byproducts for Cargill; and Kent Swisher, currently vice president of international programs and incoming president for the North American Renderers Association (NARA), gave more details about how beef byproducts are utilized post-packing plant through the process of rendering.

Rendering is the conversion of raw material into more useful products. Rendering goes hand in hand with beef processing. Many packing facilities include an on-site rendering plant. If a plant is smaller or lacks the means to include one, contracting with an independent renderer is necessary to get the most out of each carcass.

After the cuts of meat in demand in the U.S. are removed from the carcass, the upcycle process begins. The first move is to harvest other cuts or parts of the animal that, unpopular in the U.S., are in demand on a global scale. These items, collectively termed variety meats, make up a large proportion of U.S. beef exports. These include tongue, head meat, cheek meat, tongue root trim, oxlips, liver, tripe, honeycomb tripe, omasum, abomasum, small intestines, heart, oxtails, sweetbreads, kidneys, bile and gallstones.

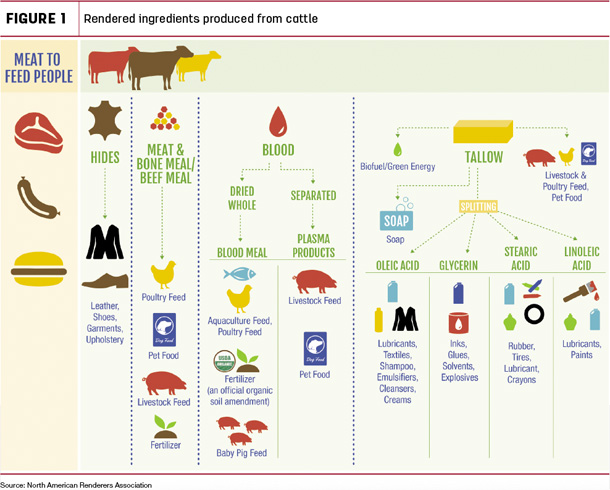

The rest of the raw material – bones, scraps and fat – are then turned over to the rendering plant. The end goal of rendering is to separate protein from fat. The blood and protein will eventually turn into products like fertilizer and aquaculture feed, and the fat becomes tallow, which gets used in products ranging from biofuel to tires and shampoo (see Figure 1).

Swisher said that in the past, the rendering industry was known as “the silent industry.” Rendering is an admittedly unglamorous industry, which tends to blend into the background and work behind the scenes. However, another equally accurate descriptor is that renderers are the original recyclers, going back hundreds, even thousands of years to when every part of a butchered cow was used in some way and nothing was wasted – compared to today, where in the U.S. only half of a butchered cow is consumed.

Even before the current societal and political focus on climate change, sustainability has become an important factor from an industrial standpoint. “Sustainability is great, and we’re sustainable,” he said. “But you can’t just say it; you have to quantify it.” Around 2012, the NARA started conducting a life cycle analysis of the rendering industry with the help of Dr. Charles Gooding from Clemson University.

Sustainability, as defined by the UN in 1987, is “development that meets the needs of the present without compromising the ability of future generations to meet their own needs.” That definition revolves around three pillars: environment, economy and society.

Sustainability by the numbers

The goal for most industries regarding sustainability focuses on reaching “net zero.” Net zero, as defined by the EPA, is consuming only as much energy as is produced, achieving a sustainable balance between water availability and demand, and eliminating solid waste sent to landfills. As the “original recyclers,” the rendering industry sequesters five times as many greenhouse gases as it produces. “We’ve already gone beyond [net zero], so I guess where we need to go now is benchmarking to improve upon that,” Swisher said.

He pointed out that the societal development and cultural changes in the U.S. have changed consumers’ choices regarding meat. In less-developed countries, the level of rendering capability in the U.S. is not necessary. “We’re recycling items that in many parts of the world are eaten. Rendering in developed societies depends on the fact that we only eat 50 percent of the animal. In many undeveloped countries, the entire animal disappears.”

Swisher also shared some key sustainability statistics gleaned from Gooding’s rendering life cycle analysis.

- U.S. renderers collect 56 billion pounds of raw materials a year and recycle them by cooking and drying into 22 billion pounds of animal fats/oils and proteins each year.

- Grocery stores generate 1.92 billion pounds of scraps, fat, bone, expired meat and used cooking oil annually.

- Renderers collect 4.4 billion pounds of used cooking oil per year in the U.S. and Canada.

- Landfill space: If all renderable products were sent to landfills instead of processed, all available space would be gone in four years.

- Water reclamation: 3.7 billion gallons of water that would otherwise be wasted are reclaimed during rendering, cleaned and returned to rivers and streams. Rendering also improves water quality by reducing grease and oil that clog sewer and wastewater systems.

- Combating climate change: Rendering reduces animal agriculture’s carbon footprint by sequestering five times more greenhouse gases than are produced. This is equivalent to removing 18.5 million cars off the road each year.

- The U.S. rendering industry accounts for $10 billion in annual economic activity across the country, including rural America.

- Almost 20% of U.S. rendered products are exported. The U.S. is the second-largest exporter of biodiesel and renewable diesel, which is made from rendered products including beef byproducts like tallow and other products like used cooking oil. In 2019, the U.S. exported more than 20 million metric tons of biofuel.

Kent Swisher also joined Carrie Veselka on a Progressive Cattle podcast. Listen to their discussion (47:50) and more NCBA 2021 coverage here.