Ty Lawrence, an animal science professor at West Texas A&M University, says the USDA beef yield grading system needs an update to match the current type of cattle in the agriculture industry.

“The system was created from cattle that were harvested in the 1950s,” Lawrence says. “That’s the problem; it’s out of date.”

60-plus years of change

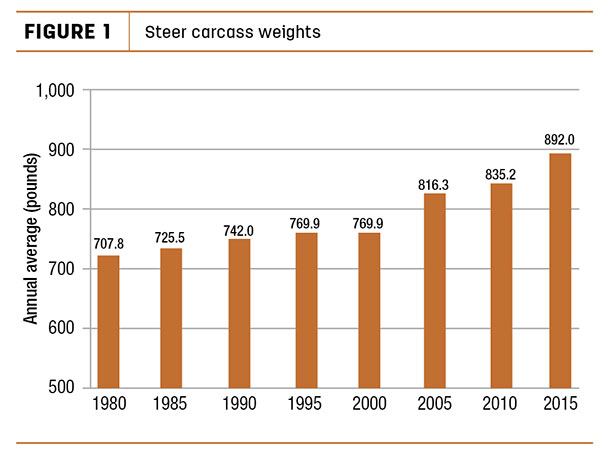

According to Lawrence, the average hot carcass weight in the 1950s was 600 pounds. Currently, the average hot carcass weight is 900 pounds.

“The carcass today weighs about what the live animal did when the system was created,” Lawrence says. “Cattle don’t look like they did in the 1950s.”

Changes in genetics, breeds and feeding mechanisms are a few things Lawrence mentions that transformed the way cattle look. Angus has replaced Hereford as the dominant breed, and black cattle lead the commercial enterprises.

“There has been a change in animal genetics,” Lawrence says. “Crossbreeds are now extremely common in our commercial enterprises, and a crossbreed of some kind dominates any purebred line.”

The yield grading system was modeled from research that looked at 162 cattle. According to Lawrence, those cattle were fed a very specific diet – a diet no longer relevant in today’s industry.

“A ration is not a ration anymore,” Lawrence says, referring to the standard “John Deere” ration which only consisted of corn and alfalfa. “Now it is highly dependent upon where you are in the country and what is the most cost-effective thing you can put in front of the cattle.”

Feed varieties, supplements and additives have increased the amount of protein and fat cattle intake prior to harvest.

“We feed a litany of byproducts now that basically changed the way fat increased, the way protein increased,” Lawrence says, “and changed the endpoint of the animal.”

According to Lawrence, dairy cattle were not even included in the 162-animal study, and now the Holstein steer accounts for 10 percent of the beef supply in today’s market.

“We need to start over,” Lawrence says. “Create a system that will represent genetic diversity and ration diversity.”

Bringing consistency with technology

In 2009, yield graders in meat packing plants began using cameras to bring consistency to grading. A camera will capture a photo of the carcass’s ribeye, analyze the marbling and back fat of the animal, and then use the results to determine yield and quality grade.

“This was offered to packers to reduce error and improve repeatability of grade,” Lawrence says. “Two packers may look at a carcass differently.”

The grader is still involved and stands by the camera to confirm or deny the grade and observe other attributes of the carcass. According to Bucky Gwartney, USDA Agricultural Marketing Service international marketing specialist, this past year the USDA updated the instrument grading technologies to include weight factors when it comes to yield grades.

“Even though marbling is a major component of quality grading, you also have to determine skeletal maturity, and that’s a greater function, so graders have to be able to identify those on every carcass,” Gwartney says. “The packer is still very much involved.”

Some packers use the cameras only for internal use. According to Gwartney, the camera is able to grade yield to the nearest one-tenth point. With this accuracy, packers can easily separate carcasses into groups with different specifications.

“The camera is really good and objective in the measurements it’s going to give,” Gwartney says.

For example, a camera will grade a carcass a 3.9 instead of a general 3. This allows packers to accurately place similar carcasses together. Gwartney says these exact grades are heavily used in the industry, but it is not officially applied as a grade on the carcass.

“It is very good technology,” Gwartney says. “But you have to remember the grader is still in charge and has oversight and the ability to override.”

Gwartney says almost more than half of packers are using instrument grading and it continues to grow every year.

“More and more, packers are realizing for value-based sales, an update is needed,” Lawrence says.

Current phase

Gwartney doesn’t think the yield grading system is outdated, but agrees the cattle population has changed.

“We note that cattle are heavier than they have ever been,” Gwartney says. “We are not sure if the yield grade system needs updated; we have heard things, but nothing formal has come across our desk.”

According to Gwartney, the Canada grading agency has done a significant research project on yield grades.

“Their grades mirror our grades very closely,” Gwartney says. “Similar types of marbling standards and yield grade standards because we do trade a lot of cattle back and forth.”

Gwartney says Canada will be releasing that information but not any time in the near future.

Jeff Smith operates a family-owned meat packing plant in northern Utah and has been working in the industry all of his life. He says he would support an update to the yield grade systems.

“I just think the cattle industry has changed quite a bit,” Smith says. “Consumer trends and demands have changed, and it’s been a long time since it was updated.” ![]()

-

Jamie Hawley

- Freelance Writer

- Logan, Utah

- Email Jamie Hawley

USDA beef yield grades

Yield Grade 1

A carcass in Yield Grade 1 usually has only a thin layer of external fat over the ribs, loins, rumps and clods, and slight deposits of fat in the flanks and cod or udder. There is usually a very thin layer of fat over the outside of the rounds and over the tops of the shoulders and necks. Muscles are usually visible through the fat in many areas of the carcass.

Yield Grade 2

A carcass in Yield Grade 2 usually is nearly completely covered with fat, but the lean is plainly visible through the fat over the outside of the rounds, the tops of the shoulders and the necks. There usually is a slightly thin layer of fat over the loins, ribs and inside rounds, and the fat over the rumps, hips and clods usually is slightly thick. There are usually small deposits of fat in the flanks and cod or udder.

Yield Grade 3

A carcass in Yield Grade 3 usually is completely covered with fat, and the lean usually is visible through the fat only on the necks and the lower part of the outside of the rounds. There usually is a slightly thick layer of fat over the loins, ribs and inside rounds, and the fat over the rumps, hips and clods usually is moderately thick. There usually are slightly large deposits of fat in the flanks and cod or udder.

Yield Grade 4

A carcass in Yield Grade 4 usually is completely covered with fat. The only muscles usually visible are those on the shanks and over the outside of the plates and flanks. There usually is a moderately thick layer of fat over the loins, ribs and inside rounds, and the fat over the rumps, hips and clods usually is thick. There usually are large deposits of fat in the flanks and cod or udder.

Yield Grade 5

A carcass in Yield Grade 5 usually has more fat on all of the various parts, a smaller area of ribeye and more kidney, pelvic and heart fat than a carcass in Yield Grade 4.

—Taken from the USDA website