In 2012, 374 farmers, stockmen and workers died from a work-related injury, according to the Centers for Disease Control and Prevention (CDC). Types of accidents include rollovers, runovers and entanglement.

Tractor farm equipment manufacturers strive diligently to reduce the number of injuries and deaths by designing and installing a large array of safety features on today’s tractors. It is impossible, however, to completely protect operators from injury unless they assume responsibility for their safety.

Of the 374 who died in 2012, tractor overturns were the leading cause. The most effective way to prevent tractor turnover deaths is the use of a rollover protective structure (ROPS).

Use of ROPS and a seat belt is estimated to be 99 percent effective in preventing death or serious injury in the event of tractor rollover. In 2012, only 59 percent of tractors used on U.S. farms and ranches were equipped with ROPS.

The first ROPS device was not marketed on new tractors until 1965. Penn State Extension says, “Between 1967 and 1985, U.S. farm tractor manufacturers provided ROPS as optional equipment on most tractor models.

This meant that new tractor purchasers had to add the cost of a ROPS onto the base price of a tractor.

“Because most farmers and ranchers are cost-conscious, few added ROPS as an option. Even fewer pre-1976 tractors have ROPS, yet many of these tractors are still in use.

Beginning in 1985, American tractor manufacturers began voluntarily adding ROPS and seat belts on all farm tractors over 20 horsepower.”

The modern farm tractor

Manufacturers have gone way beyond ROPS and seat belts in adding safety devices to today’s tractors. Many features add comfort and reduce fatigue, which helps keep the operator alert and aware of any potentially dangerous situations.

“John Deere has enclosed all operating control linkage in hoods or covers to prevent hand and foot injuries,” says David Crouch, sales rep at the Coufal-Prater location in Taylor, Texas.

“A ‘park’ position has been added to the transmission, which allows the operator to lock the drivetrain when he is off the tractor. If the power take-off is running, a switch shuts it off when the operator leaves the seat.

“Suspension in the front axle provides a smooth ride and makes the tractor easier to operate. Cabs, completely enclosed with shatter-proof glass, provide spacious high visibility, which adds to the safety of the operator plus those around his work area.”

The tilt and telescoping steering wheel and adjustable air seat adds to operator comfort and ease of operation. The optional John Deere CommandARM moves with the seat. This device is used to control the throttle, speed, hydraulics, PTO (power take-off), hitch adjustments and more.

“Case IH and New Holland tractor cabs have been re-designed to provide easier and safer entry and exit,” says Rick Thornton, sales manager with Williamson County Equipment Company in Taylor. “The suspended cab option is a continuously active, stand-alone system that reduces shock loads by 25 percent.

“Suspended ladders provide better access to the cab, and seat belts are standard on all models. The SurroundVision cab with shatter-proof glass provides an unobstructed 360-degree view for clear sight to front-mounted and rear-mounted implements.

Standard on some models and optimal on others, the shatter-proof roof panel lets the operator keep an eye on the loader in a raised position.

“Controls have been repositioned in the cab for better accessibility,” Thornton continues. “The MultiControl armrest allows the operator to set and control speed, shift gears, change direction and control the hitch and hydraulics without lifting the elbow.

For increased safety, a more positive park gear locks the tractor in place when the operator leaves the cab. Both interior and exterior lighting has been improved to make night work easier and safer. Some models have step lights that come on and stay on as the operator leaves the cab.”

“All major brands of tractors have essentially the same safety devices,” says Crouch. “We’re all committed to making tractor operation as safe as possible.”

“We, as most equipment dealers, take our customers through ‘Tractor Operation 101’ when they buy a piece of equipment,” says Thornton. “The new owner is taught how to start and stop the tractor, use all the controls and operate it safely.

We spend a lot of time instructing the customer on how to use the tractor on slopes since this is where most of the rollovers occur.”

Skid-steer loaders

Skid-steer loaders have replaced the farm tractor for many jobs in feedlots, hay farms and cow-calf operations because of its smaller size and maneuverability. Also known as a skid loader or skid steer, the skid-steer loader has a small rigid frame, a rear engine and arms for attaching a wide variety of implements.

Wikipedia describes skid-steer loaders as typically having four wheels mechanically locked in synchronization on each side. Left-side drive wheels can be driven independently of the right-side drive wheels, and all four wheels hold a fixed straight alignment on the body of the machine.

The machine is maneuvered by skidding, or dragging slow-turning wheels on one side with faster-turning wheels on the other. The machine received its names from this turning action.

Caterpillar introduced new Cat D series skid-steer loaders during 2013 that are loaded with electronics that enhance operator safety, comfort and handling ease.

The cab design includes superior sealing, which allows doubling cab pressurization from that attained with previous designs. These enhancements provide a cleaner working environment plus improved air conditioning and heating.

“Options include a high-back, heated, air-suspension seat that incorporates integral mounted joystick controls,” says Sharon Holling, Cat trade press media representative.

“The seat provides additional comfort through recline and lumbar adjustments. All air-suspension seats feature independent arm bar/joystick control adjustments to allow the machine to be configured for different size operators and for different applications.

“This arrangement also allows the entire seat/joystick control package to move up and down as a unit, minimizing operator fatigue and maximizing comfort. Safety is enhanced with a rear-view camera that provides additional work site visibility, especially when working in tight applications.

“Lift arms for all D series machines are a new tubular design that retains excellent lift characteristics and strength while presenting a narrower profile,” Holling continues.

“The sleek lift arm design improves sight lines to the sides of the machine, to the tires and to the work-tool/coupler interface which provides enhanced visibility and site safety.”

“An adjustable pull-down padded lap bar provides comfortable arm support on John Deere skid-steer loaders,” says Crouch. “The lap bar plus a seat belt keeps the operator securely in the machine. An additional safety feature is a triple-interlock operator-presence system that automatically applies the brakes when the lap bar is raised. Another switch shuts down the engine when the operator leaves the seat.”

Equipment manufacturers can improve products to deliver a machine that is safe to operate, but the operator has the ultimate responsibility to use machinery in a safe manner.

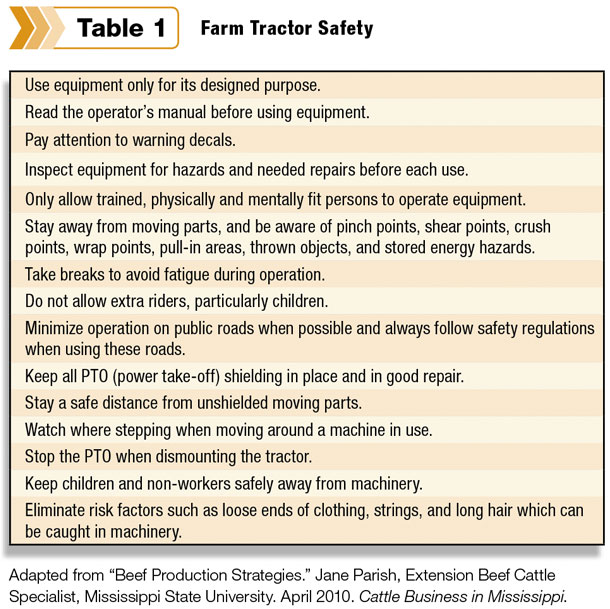

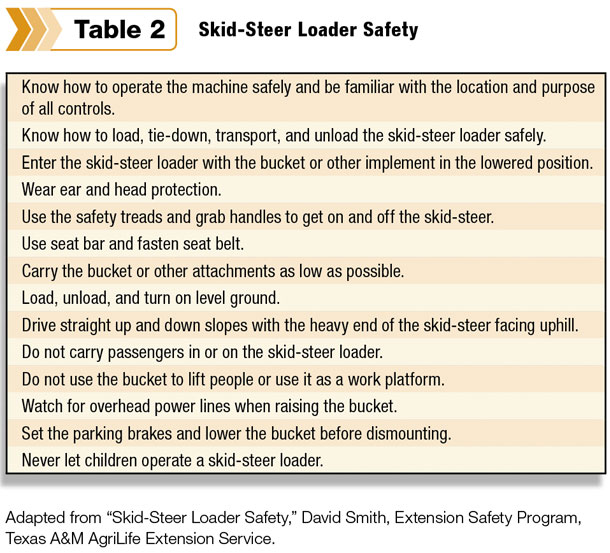

Additional care needs to be taken with older equipment that does not have the safety devices of today’s products. Tables 1 and 2 (above) list some of the safety procedures that should be followed. ![]()

Robert Fears is a freelance writer based in Texas.