There are important questions you must ask when sourcing your DGS to ensure you are getting a consistent, high-quality product for your cattle.

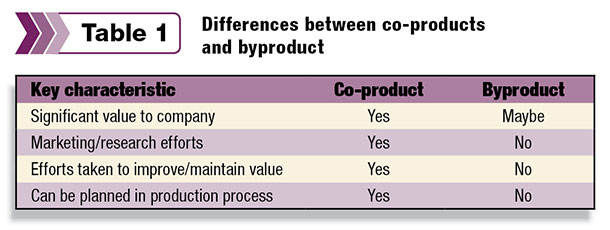

Table 1 highlights the key differences between a co-product and a byproduct.

When DGS first entered the scene, people who formulated feed rations were cautious about using them because they had poor experiences with product consistency. DGS were leftovers as ethanol plants focused primarily on making ethanol. As such, DGS were the very definition of a “byproduct.”

Beef researchers started to investigate the nutritional characteristics of DGS and quickly identified their value. Several ethanol plants did as well, and they invested in marketing to increase the demand for products. Suddenly DGS were moving from a byproduct to a co-product.

Ethanol plants started to direct efforts towards improving or maintaining the value of the co-products with practices such as improved testing, maintaining consistency and monitoring drying conditions to avoid heat damage.

These practices continue to evolve today, and progressive ethanol producers consider the impact of process changes on all their products. At the same time, they look for opportunities to alter feed characteristics to create even more value.

Modern-day ethanol production has transformed much of the industry from “ethanol plants” to “biorefineries” that produce multiple, high-quality products from corn. DGS, corn oil, carbon dioxide and other products no longer take a back seat to ethanol. They are true “co-products.”

It is important to know whether your supplier considers DGS a byproduct or a co-product.

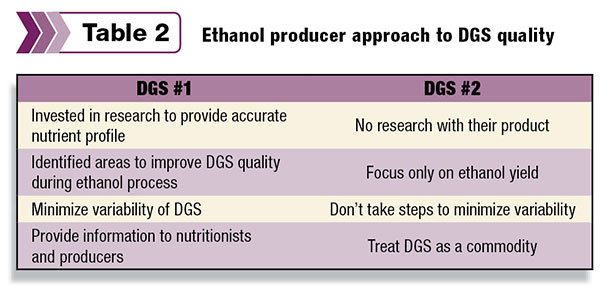

For example, let’s consider DGS from two different suppliers (Table 2).

Which DGS will nutritionists have more confidence in when formulating diets? The first supplier has focused on producing a true co-product with a consistent nutrient profile.

Meanwhile, the second supplier continues to provide a byproduct that potentially has much more variability. All of this variability can lead to poorer animal performance and ultimately, reduced profitability.

With all the ethanol plants, and a large supply of DGS, it can be difficult to identify if your DGS comes from a supplier that has a co-product or byproduct focus. Nutritionists and producers need to ask questions of their suppliers:

What areas of the ethanol process have they focused on to improve DGS quality?

What steps have they taken to improve the consistency of the DGS?

What research have they conducted with their product? What has that research demonstrated and how have they used it to help animal performance?

What are some potential areas that are being investigated to improve the value of DGS?

Although the difference between a co-product and a byproduct might seem insignificant, it is an important factor when comparing DGS.

The different focuses on quality, consistency and innovation can quickly differentiate DGS by providing a better characterization and understanding of the specific source. This understanding provides more information to the nutritionist, which ultimately leads to improved animal performance and profitability. ![]()

-

Kevin Herrick

- Technical Services Director – Nutrition

- POET

- Email Kevin Herrick