So in an effort to keep everyone on the same page, monthly administration training and reoccurring implant checks are enforced to help reach the desired outcome of the implant.

Without consistency in the proper application and sanitation methods, McLennan points out that implants can become a waste of valued time and money.

“Administration training is a form of people management,” McLennan says. “You are paying for these implants and you are paying people to put them in. If the crew doesn’t use the proper techniques, it can cost you money down the road. I have always been taught that if you can’t measure it, you can’t manage it."

"An implant check is essentially a way to measure the employees that are administering the implants, vaccines and all the different interventions that are part of your management. You rely on those people to do it correctly, so it is important you train and check up on them often.”

Correct administration, big benefits

According to the Mississippi State University Extension Service, improperly placed implants can cause implant to be less effective or even ineffective. Producers should never lower their standards of proper placement and sanitation for speed.

Slowing the implant crew down will not only help minimize animal stress but will also help maximize the success of the implant.

Almost all failures in implant productivity can be prevented with consistent training and checks. Some common causes of implant failures include:

- Abscess formation (due to poor sanitation or administration techniques)

- Missing implants (through the ear)

- Partially missing implants (due to gun failure or poor administration)

- Crushed or bunched implant pellets

- Inadequate implant storage (Review label instructions before storage and use.)

- Applying implants in the wrong area (cartilage)

If done properly, the economic benefit of implanting beef cattle can be beyond the cost of the implants. In another publication by the University of Arkansas, researchers stated that proper use of implants return $10 on every $1 invested.

Implants are designed to complement good management; however, it is important producers keep in mind that implants do not compensate for poor management.

Implants are designed to complement good management; however, it is important producers keep in mind that implants do not compensate for poor management.

“The implant is extremely important to our operation,” McLennan says. “If the employees are willing to receive training, follow through, do the procedure correctly, and if they are willing to be held accountable for their work, you can find comfort in knowing they are also giving injections with the proper placement, handling the cattle correctly and so on.”

Training and checking for proper procedures

Dr. John Hutcheson, director of technical services at Merck Animal Health, urges producers to stress the importance of properly administering implants to their employees.

The implant crew needs to understand the economic liability involved with the process, he says. If they don’t understand the process, they can’t really be held accountable for their actions.

Hutcheson suggests selecting the most conscientious employees to administer implants. Then occasionally check the crew members’ techniques to make sure they are upholding the proper methods. It is important that these crew members have been adequately trained to be put in charge of such an integral form of management, he says.

Training should be an essential part of the process at all cattle operations using implants, since it has such a large economic impact to the operation.

Producers can also decide to have representatives assist with training and checks, Hutcheson says. His company’s representatives, for example, can work with customers or people who administer implants on their operation.

They train people on the proper sanitation and proper procedures, and then they follow that up with a quality-control verification program to evaluate how they are doing and how they performed the process in a select group of animals, he says.

They train people on the proper sanitation and proper procedures, and then they follow that up with a quality-control verification program to evaluate how they are doing and how they performed the process in a select group of animals, he says.

“People are what make implants happen. So getting the people trained and helping them to understand why they are doing it will benefit you in the long run,” Hutcheson says.

Below are five steps that should be enforced in training and implant checks to maximize the value of the implant.

1. Determine if the implant applicator (implant gun) is designed for the specific implant intended. Often times, manufacturers make specific applicators for certain types of implants.

Using the correct applicator will minimize defects. Then load the applicator according to label instructions. Only use needles that have been disinfected after each application and refrain from using dull needles.

2. Make sure the animal is restrained properly. The restraining method often depends on what stage of production the animal is receiving the implant.

3. Once the animal is properly restrained, select an ear for implanting. Disinfect the ear at the insertion site and get rid of any remaining debris. Position the needle so it is parallel to the ear and find the proper location.

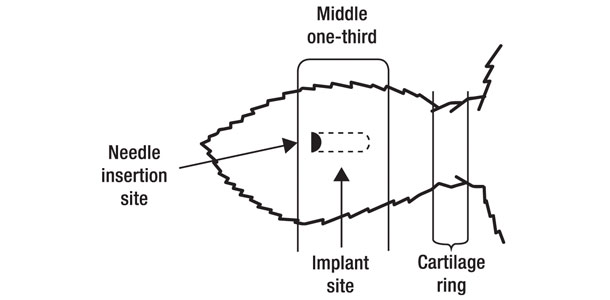

The implant should be inserted at the middle third of the ear between the skin and the cartilage. This is the only area the FDA has approved for application.

4. Press the trigger to release the pellets into the ear and slowly withdraw the applicator parallel to the ear. Then feel the ear to determine if the implant pellets were inserted correctly. (The pellets should not be bunched or crushed.)

It can also be a good practice to pinch the area where the needle was inserted to help close the opening.

5. Make sure to disinfect the needle, with chlorhexidine or any other suitable disinfectant, before each application and wipe the applicator with gauze to get rid of any remaining debris from the prior application. Proper sanitation will lower the chance of an abscess.

Other considerations for ensuring projected growth

Dr. Kara Thornton, a post-doctoral research associate at the University of Minnesota, has been involved with some extensive research involving implanted beef cattle.

She notes that if implants are not applied properly, producers essentially lose money, not only because of the time and cost of the implant but because of the added stress presented to the animal.

“Any time the animal is run through the chute or restrained in some way, it is often really stressful for that animal. Some animals will come off feed for a couple of days or even up to one week.

So it becomes even more important that these implants are applied correctly,” Thornton says. “If the implant crew isn’t careful, they could alter their projected amount of growth.”

Thornton points out that if people are doing the process correctly, they will check the animal before it is released.

By following protocols and providing employees with adequate instruction, owners and managers can see substantial returns on their investment. The implanting process is never something that can be rushed or overlooked, she says.

So whether it’s a cow-calf, stocker or feedyard operation, producers are strongly encouraged to incorporate an implant training program and regular checks on their operation.

Doing so will not only help operations reach their projected growth but will help owners and managers rest a little easier knowing their employees are taking the necessary steps to maintain a profitable animal. ![]()

Cassidy Woolsey is a freelance writer based in Utah.

PHOTOS

PHOTO 1: Implants should be placed in the middle one-third portion of the ear. Employees that administer implants should be trained properly on placement. Photo courtesy of Merck Animal Health.

Illustration: Proper implant placement. Illustration courtesy of Jack Whittier.

PHOTO 2: Implanting tool, tray with disinfectant, brush (for cleaning ears) are all tools that should be used for proper implanting. Photo courtesy of Merck Animal Health.