However, throughout storage the ensiled material is still going through changes that will impact the characteristics of the silage to be fed to the animals.

The most evident change that occurs in feeds such as high-moisture corn and corn silage with longer storage time is the increasing starch digestibility.

Recent research from Pat Hoffman’s group at University of Wisconsin suggested that the reason for this phenomenon is the partial solubilization of the prolamines, which form a protein matrix that encapsulates the starch granules.

The effect of prolamines on starch digestibility is influenced by a number of factors:

- The cultivar, floury endosperm varieties have starch granules less imbedded in the protein matrix

- Storage time

- Moisture content

There is also some evidence in the literature reporting that longer silage storage time can increase fiber digestion; the fermentation acids may solubilize some fractions of the hemicelluloses complex.

Monitoring silos

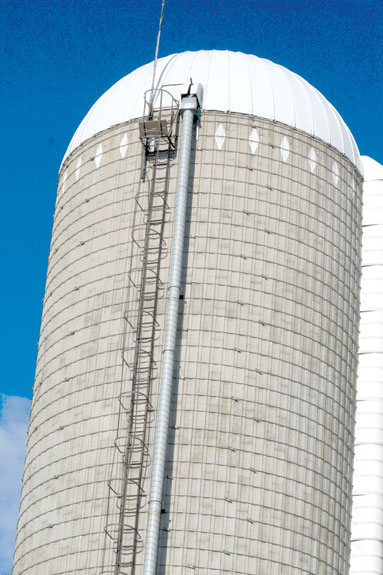

It is also essential to keep an eye on silos during the storage phase.

Silo bags and plastic covers can be damaged by animals, people, elements and farm machinery; concrete walls of tower silos are porous to air exchange into the forage and the silage acids produced can increase this porosity.

Storage structures should also be inspected for cracks, particularly in bunkers for wall panel joint cracks.

The entrance of air during storage can result in considerable spoilage of silage; therefore, there should be constant monitoring and repairing as needed.

Water entering the silage can also be detrimental to silage quality.

If water enters the silage mass and causes seepage, part of the soluble nutrients and fermentation acids will be lost, leading to higher pH.

Water can also bring in oxygen to opportunistic spoilage microbes and, along with higher pH, will result in faster rate of deterioration.

2012: Effects of the drought

The record hot and dry weather this year impacted the agriculture industry in diverse ways and at different levels.

By the time this article was written, there were several reports of Aspergillus ear rot in corn fields.

This disease is caused by two molds that may produce aflatoxins, an extremely toxic compound; in addition, hot, dry conditions during grain fill – as seen this year – can increase the risk of aflatoxin production.

If potential toxin contamination is a concern, representative samples of the silage should be sent to an accredited laboratory for mycotoxins analysis.

The FDA guidelines for acceptable aflatoxin levels in corn for breeding meat cattle and for finishing cattle is less than 100 ppb and less than 300 ppb, respectively.

These molds need ears and or kernels on the ears to develop and potentially produce aflatoxins – for salvage corn without ears or kernels, this won’t be an issue.

However, dry distillers grains resulting from ethanol production that used infected corn will have more concentrated levels of aflatoxins.

The addition of a mycotoxin binder such as yeast cell wall extracts or MOS products and clay binders may reduce the effects of aflatoxins in animals.

Another condition related to drought-stressed forages is the higher concentration of nitrates that may accumulate in the plant.

There are several factors that impact the level of nitrates in the chopped forage that was put in the silo:

- A heavy rain during the drought increases the absorption of nitrates by plants

- If the plant was high-chopped, most of the nitrates will stay in the stalks left in the field, since nitrates accumulate in the bottom third of the plant

- Crops ensiled at right moisture content and under good management (using an inoculant, filling quick, packing tight and covering immediately) will go through a good fermentation, which can reduce the concentration of nitrates by approximately 50 percent.

Elevated levels of nitrates can also increase the potential for silo gas, specifically nitrogen dioxide (NO2). NO2 is a heavy, yellow-orange gas that smells like bleach, and its exposure can cause lung damage or even immediate death.

If necessary to go inside the silo, make sure that a blower runs for 30 minutes and wear a gas mask/respirator.

Prussic acid may also accumulate in sorghum/grass silages when growing rapidly after a stress (drought) situation.

Field wilting or field drying will release around 60 percent of the prussic acid and, as it occurs with nitrates, the bottom part of the stem is what presents the most danger.

Drought-stressed corn ensiled has decreased yield and may also have a lower grain concentration and consequently higher NDF content and lower starch and energy concentrations.

Drought-stressed corn produces a different type of silage but its feeding can be managed as long as representative samples are taken and sent for complete analysis – and the required adjustments in the diet made.

Renato Schmidt is a forage technical specialist for Lallemand.

Bob Charley is technical services manager at Lallemand.

PHOTOS

TOP: Drought-stressed corn produces a different type of silage but its feeding can be managed as long as representative samples are taken.

MIDDLE and BOTTOM: Because the walls of concrete silos are porous to air, structures should be inspected for cracks in wall panels and joints to help preserve forage. Photos courtesy of Progressive Cattleman staff.