It is also estimated that the dry matter (DM) loss in this corn silage will be between 15 and 20 percent, for a staggering loss of $1.1 to $1.5 billion.

DM losses also have a negative impact on the nutritional value of the remaining silage since shrink consumes the most valuable silage nutrients, which must then be replaced with an equal energy source, such as corn grain.

In some beef and dairy operations, one person is responsible for the growing, harvesting and storage of the silage crop. In many instances, though, these responsibilities are contracted out, which can make effective communication, planning and coordination more complex from harvest through feedout.

Shrink can come in many forms, including mechanical, wind, fermentation, seepage, hot feed, mixing errors, scale inaccuracy, storage, feedout, surface management, feed refusals, spoilage, birds and rodents. This article will focus on silage storage and feedout shrink.

Today’s record-high beef prices and tight forage supplies require forage best management practices.

Fermentation principles

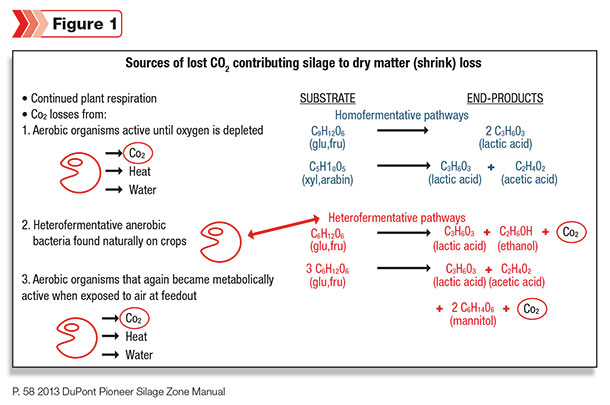

DM loss (shrink) begins with plant cell respiration and aerobic microflora utilizing carbohydrate sources (primarily sugar) to produce water, heat and carbon dioxide.

It is this carbon, lost to the atmosphere in the form of carbon dioxide, that causes shrink loss. These processes will continue until the oxygen in the silage mass is depleted.

Adequate moisture to reduce silage porosity and adequate compaction play a key role in reducing the length of this initial aerobic phase. The estimated net energy loss (in pure starch equivalents) from this initial aerobic activity is 1 to 2 percent, and the loss is largely unavoidable.

The subsequent anaerobic conditions establish an environment suitable for domination by homofermentative and heterofermentative lactic-acid bacteria (LAB). There would be no shrink loss in this phase if only homofermentative LAB were active.

However, less than 0.5 percent of epiphytic organisms found naturally on fresh crops are LAB, and only a small proportion of these are homofermentative LAB. Their job is to drop the pH as rapidly and low as possible to reduce DM losses on the front end of the fermentation process.

To put the loss from heterofermentative LAB in perspective, there is a 24 percent loss of DM from the heterofermentative fermentation of glucose. It’s the heterofermentative LAB’s job to inhibit yeast growth and reduce heating and losses on the back end of the fermentation process and improve fiber digestibility.

The average net energy loss (in pure starch equivalents) from epiphytic LAB fermentation is 4 percent. These anaerobic fermentation losses can be reduced by 25 percent or more with the use of homofermentative strains found in reputable silage inoculants.

Aerobic losses

The re-exposure of silage to aerobic conditions happen in two ways: top and side exposure during storage, and face exposure during feedout.

The combination of these two causes of shrink loss can vary significantly depending on management practices, but estimates of more than a 20 percent loss in net energy (in pure starch equivalents) have been reported from aerobically unstable silages.

More than 20 percent of the silage will be contained in the top 3 feet of many bunkers and drive-over piles.

The recent introduction of oxygen barrier film has certainly been a tremendous step forward in reducing the problem of top spoilage. A more pressing problem today, however, is managing shrink on the wide, exposed silage faces common on large bunkers and piles.

Two recent advances have helped reduce aerobic face losses: mechanical facers and inoculants containing Lactobacillus buchneri strains, which have been proven to reduce spoilage yeast growth.

Monitoring storage and feedout challenges

One way to identify storage and feedout issues is temperature monitoring. Tools that can be used to measure silage heating include infrared thermal-imaging cameras, compost thermometers and digital thermometers.

There are two types of silage heating: physiological heating and microbial heating. Physiological heating is the heat produced by plant respiration during the initial aerobic fermentation phase.

Microbial heating is the secondary heating that occurs after air has been reintroduced to the fermented silage.

If your silage begins heating beyond 10 to 20ºF above the ambient temperature at which it was harvested, it could signal some challenges.

Common management causes of microbial heating occur when the silage face is left open for an extended period of time, if there are uneven or jagged cuts on the silage face, or in cases of poor packing and low DM densities.

To reduce microbial heating, manage forage to prevent air penetration and use a research-proven silage inoculant containing Lactobacillus buchneri strains.

Five steps to achieve single-digit silage shrink

- Create bunkers and piles in optimal shapes and sizes. Shape drive-over piles using a 3-to-1 ratio. The pile should also be packed from back to front and side to side.

Many producers try to put too much silage into spaces that are too small to accommodate that volume, which results in piles or bunkers with side slopes at a one-to-one ratio or less that tower 20 to 25 feet high. Piles like these make it impossible for the tractor operator to pack the sides and are unsafe. - Achieve a low silage porosity score or a high silage DM density score. Bunkers or piles should be packed tightly. Silage should be spread in 6-inch layers or less, decreasing in thickness as elevation increases.

The thumb rule is to apply 800 pounds of packing weight for every ton per hour of forage delivered to the pile or bunker. - Provide an effective seal. When covered properly, the improvement of feed quality provides an 8-to-1 return on investment. Use two sheets of plastic or an oxygen barrier film and cover the sidewalls.

- Apply a research-proven, high-quality inoculant that can result in faster, more efficient fermentation and increased DM recovery.

- Manage the exposed forage during feedout. To minimize DM losses after opening the pile or bunker, use de-facing equipment to remove at least 6 to 12 inches from the face per day during cool weather and possibly up to 18 inches during warm weather. Then feed the forage within 24 hours of removing it from the pile or bunker.

Bill Ramsey is the western livestock information manager with DuPont Pioneer.

References omitted due to space but are available upon request. Click here to email an editor.