Finally, toxins in severely spoiled silage can cause production losses if fed to cattle, in addition to health and reproductive issues. Because of this progressive process, it is always advised to discard visibly moldy silage, as just about all the rumen-digestible matter has already been used.

Determining the causes of spoilage and adopting simple management changes will increase both the quantity and quality of forage available.

Don’t feed spoiled silage

Prevent self-inflicted losses to production and productivity; don’t feed visibly spoiled silage. Including spoiled feed at low rates is tempting, but even small amounts can disrupt normal rumen function – and can lead to reproduction problems or impaired cattle health.

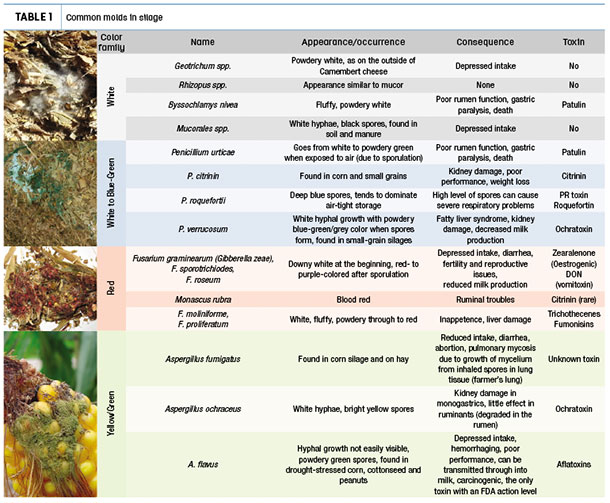

Disposing of spoiled silage can feel like throwing money away, but it may be your least expensive solution overall. Yeasts and molds in feed can cause respiratory problems, reduce intake and negatively impact production. Furthermore, some common spoilage molds may produce mycotoxins under certain circumstances, which can cause serious health issues for both dairy and beef cattle operations.

Feeding even small quantities of spoiled silage can lead to drops in intake, acidosis-like symptoms, reduced ability to digest fiber and dry matter (DM). In dairy herds, milk production and fat depressions also are common.

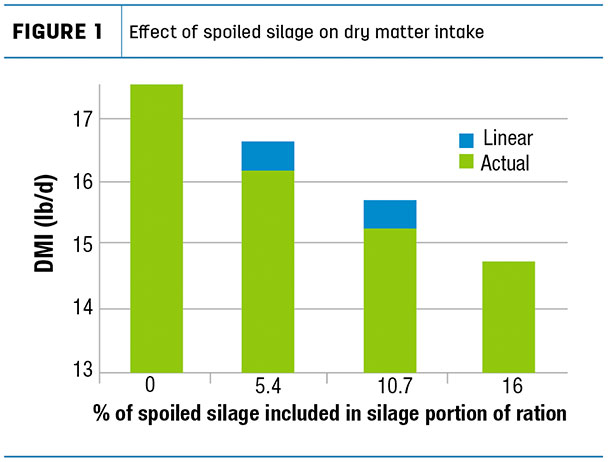

Beef cattle intake can be significantly affected by spoiled feed as well. A study by Kansas State University incorporated various levels of spoiled silage into the ration of steers. Including just 5.4% of badly spoiled silage in the ration of beef steers reduced DM intake by 1.3 pounds per day (see Figure 1).

Yeast help molds grow

Yeast are almost always the root cause of spoilage losses. Corn silage, cereal silage and high-moisture corn (HMC) often have high indigenous yeast populations. Yeasts grow best on feeds that contain starch and soluble sugars. However, yeasts cannot grow without the presence of oxygen. Therefore, silage management practices that minimize air infiltration help decrease aerobic instability.

When appropriate silage management practices are not in place, yeasts can sometimes grow, leading to increases in silage pH, which allows molds and other opportunistic spoilage microbes to grow. At this point, toxins may also be produced.

Molds can produce mycotoxins

Mycotoxins may be produced during all phases of production – from the crop in the field all the way through to the feedbunk.

Mycotoxins are climate-dependent, caused by plant- and storage-related problems. Their production is impacted by factors such as bioavailability of micronutrients, plant tissue damage and attacks from different pests, which are also influenced by climate. Therefore, mycotoxin incidence and intensity vary by year, so it is important to analyze at-risk feeds regularly.

Reduce losses and toxin sources in the field

Prevention of the growth of molds on crops in the field is vital to reduce both spoilage losses and the presence of mycotoxins. Molds are opportunistic pathogens growing on damaged or stressed plants. General risk factors for mold growth and mycotoxin production in the field are:

- Humidity at silk emergence

- Drought or flooding

- High temperatures during grain maturation

- Insect, hail or other mechanical damage to plants

- Delayed maturation and/or harvest

- Agronomic practices (e.g., zero till), use of herbicides, etc.

To reduce losses – and limit the opportunity for mycotoxin development – select locally adapted varieties with proven disease resistance. Be aware: Late-planted corn is at higher risk because of greater chances of moisture stress during flowering and grain- filling phases.

Desirable traits include general adaptation to high temperatures and drought, resistance to ear- and root-feeding insects, and a hard endosperm and a tight husk. Hybrids with transgenic insect resistance, such as Bt-hybrids, have shown reduced mycotoxin production in corn compared to conventional counterparts.

In addition, fertilize the field in accordance to the soil analysis and avoid high plant populations. Proper management of residues in the soil reduces “fungal refuges” and so the risk of mold and mycotoxin contamination. Crop rotation can also alleviate fungal buildup, in addition to reducing soil erosion and increasing crop yield.

Weeds may harbor insect and disease organisms that attack crops. The most economic and reliable way to control weeds, pests and diseases is to anticipate them. Walk the fields and scout for weeds and pests to enable timely and targeted spraying decisions, resulting in better control and reduced costs.

In addition to animal and insect damage, mechanical damage allows mold spores to disperse from plant to the soil, resulting in an inoculum for the crop in the following year. When harvesting, avoid lodged or fallen material since soil contact may increase the risk of molds and mycotoxin contamination.

Monitor forage crops

Monitor fields and consider if there were conditions that would stimulate the growth of molds and, possibly, the production of mycotoxins. Next, check if there are pockets in the field with problems such as disease or pest infestation, which could lead to hot spots of contamination – or if the whole field could be affected (e.g., extensive plant damage by a storm).

Embrace good silage management practices

Limiting, or preferably eliminating, spoiled silage is the best bet for maintaining production, herd health and preserving valuable feedstuffs. To achieve this goal, there’s no substitute for good silage management practices, including:

- Harvesting at the right stage of maturity and moisture level

- Achieving the right chop length and checking actual particle size distribution

- Treating all forages for silage with an inoculant that has relevant independent research data

- Packing well to exclude air

- Covering and sealing immediately

- Repairing any damage to silage plastic during storage

- Managing feedout by removing 6 inches or more from the face, enough to prevent heating, keeping the face straight and clean, and avoiding leaving drop piles.

When battling yeasts and molds, there’s no single additive that can replace good management techniques, but there are forage inoculants that are proven to help address stability challenges. For example, Lactobacillus buchneri 40788 applied at 400,000 colony-forming units (CFU) per gram of silage or 600,000 CFU per gram of HMC has been uniquely reviewed by the FDA and allowed to claim improved aerobic stability.

Putting these – and other good silage management practices – to work can help ensure cattle producers have high-quality silage available to fill their feedbunks and improve their productivity. ![]()

Bob Charley received his Ph.D. in microbiology from the University of Strathclyde in Glasgow and is employed by Lallemand Animal Nutrition, North America as the forage products manager, since 2002.

Renato Schmidt received his Ph.D. in animal nutrition from the University of Delaware and is employed by Lallemand Animal Nutrition, North America as a technical services – forage team member, since 2008.

References omitted but are available upon request. Click here to email an editor.