Seventy percent of the increased food production must come from efficiency-improving technology.

Improved production efficiency through technology has multiple benefits: dramatically reducing production costs, reduced land needed to produce an equivalent amount of food for consumers, limiting the production of greenhouse gases per unit of food produced and decreasing food costs to consumers.

Growth-promoting technologies have been used for more than 50 years. Anabolic steroid implants are safe and effective growth-promoting agents used in more than 90 percent of feedlot cattle.

Implants increase growth rate by 10 to 30 percent, feed efficiency by 5 to 20 percent and carcass weight by 5 to 10 percent.

Ionophores are compounds that alter the population of rumen microbes, increasing the metabolic efficiency of cattle and decreasing the amount of greenhouse gas production. Ionophores increase growth by 5 to 20 percent and feed efficiency by 20 to 25 percent.

Jude Capper estimated in 2011 that, due to increased technology, to produce the same amount of beef as we produced in 1977 we need 30 percent fewer animals, 19 percent less feed, 12 percent less water and 33 percent less land, meaning we are more sustainable now than ever before.

Adoption of technologies like ionophores and implants by cattle-finishing operations has been estimated to be more than 90 percent, but adoption by stocker producers is much lower.

Adoption of technologies like ionophores and implants by cattle-finishing operations has been estimated to be more than 90 percent, but adoption by stocker producers is much lower.

Research from Oklahoma State University estimates that adaptation of growth-promoting technologies by large-scale stocker operators is about 78 percent but is much lower with smaller-scale producers, at around 56 percent.

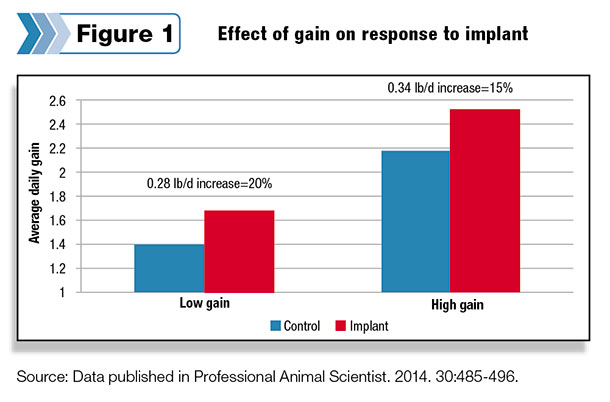

Research conducted at the University of Arkansas Southwest Research and Extension Center determined the effect of implanting steers managed on wheat pasture for either a high level of gain (stocking rates maintained at 1.5 acres per steer during the fall and winter) or a low level of gain (stocking rates maintained at 1.5 steers per acre).

Unimplanted steers managed for lower performance gained 1.4 pounds per day, while unimplanted steers managed for higher performance gained nearly 2.2 pounds per day.

Implanting, whether steers were managed for low or high rate of gain, increased average daily gain by approximately 0.3 pound per day, a 15 to 20 percent increase in performance.

So regardless if calves are set up to gain at a high level or low level of performance, the growth-promoting implants will still give the expected benefit to gain.

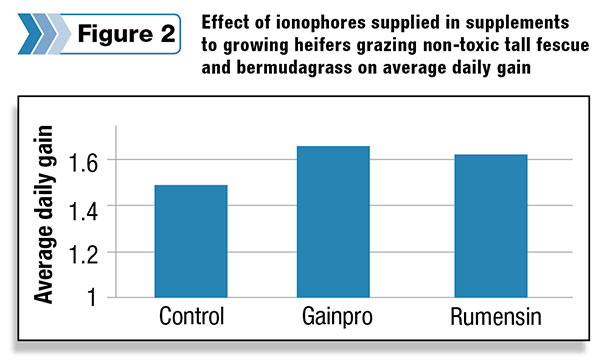

Ionophores are compounds – like Bovatec, Rumensin and Gainpro – we feed to cattle to alter ruminal metabolism, improving the efficiency of nutrient use and increasing average daily gain of grazing steers and feed efficiency of finishing cattle.

Performance of cattle fed ionophores has been shown to increase by 5 to 20 percent and feed efficiency by 20 to 25 percent.

Research we conducted at the University of Arkansas Livestock and Forestry Research Station with growing heifers indicates that when supplements fed to heifers grazing non-toxic tall fescue or bermudagrass contained ionophores (either Rumensin or Gainpro), gains were increased by 10 percent (1.49 pounds per day for control and 1.64 pounds per day for ionophores; Figure 2).

Research we conducted at the University of Arkansas Livestock and Forestry Research Station with growing heifers indicates that when supplements fed to heifers grazing non-toxic tall fescue or bermudagrass contained ionophores (either Rumensin or Gainpro), gains were increased by 10 percent (1.49 pounds per day for control and 1.64 pounds per day for ionophores; Figure 2).

This improvement in gain will have a major impact on the profitability of supplementation programs.

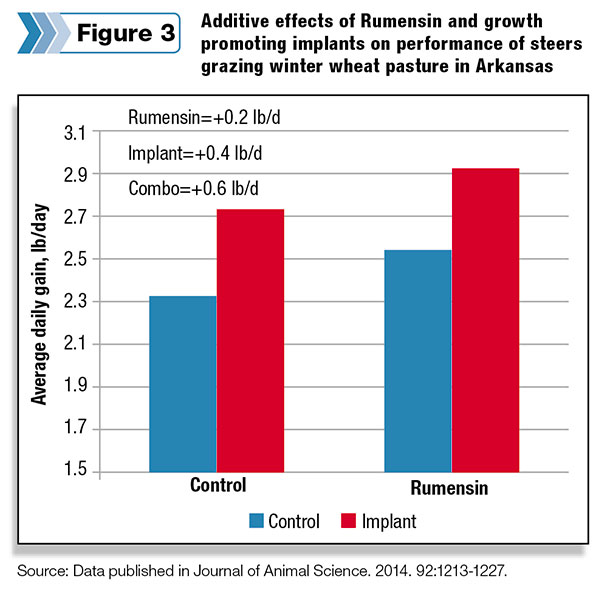

In recent research on stocker steers grazing wheat pasture at the Livestock and Forestry Research Station, steers that were neither implanted nor given the ionophore Rumensin gained 2.3 pounds per day, a very acceptable level of performance.

When steers were given Rumensin, their average daily gain increased by 0.2 pound per day to 2.5 pounds per day. When steers were implanted, whether they were fed Rumensin or not, average daily gain increased by 0.4 pound per day.

So by supplying both Rumensin and implanting growing steers, gains were increased by 0.6 pound per day to an average of 2.9 pounds per day.

So by supplying both Rumensin and implanting growing steers, gains were increased by 0.6 pound per day to an average of 2.9 pounds per day.

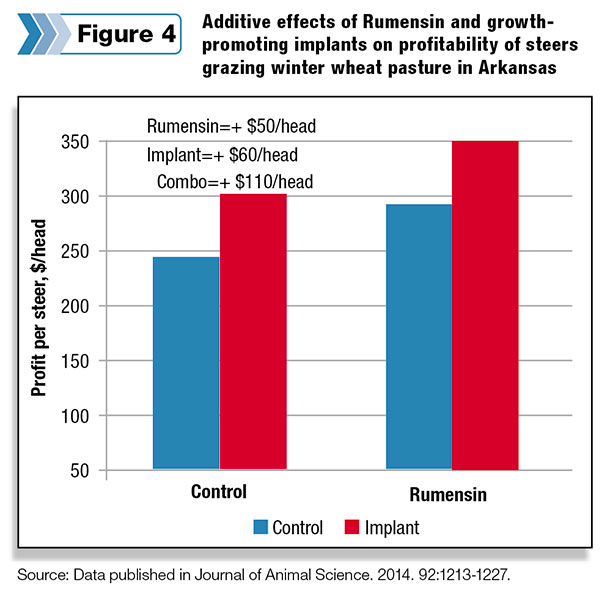

The economics of stocker production has changed over the last year; values of gain for stockers has increased to about $1.60 per pound in recent years, meaning that if cost of gains are less than $1.60 per pound, the stocker program will be profitable.

The current cost of gain in our stocker programs is around $0.80 per pound, so stocker steers gaining 300 pounds have been making about $240 per calf.

Implants add an additional $60 per steer of profitability and Rumensin adds another $50 per steer, but supplying both growth-promoting technologies adds $110 per steer in additional profit to the stocker enterprise.

Unless your steers are enrolled in a value-added all-natural program and the bonus from that program is greater than the value supplied by these technologies, there is no reason not to use these technologies in your herd.

Unless your steers are enrolled in a value-added all-natural program and the bonus from that program is greater than the value supplied by these technologies, there is no reason not to use these technologies in your herd.

It is important to remember that all production systems can be sustainable. Improvements can be made to any production system to make it more sustainable.

The beef industry is big enough for all types of production. Consumer choice is an important part of our society, and we should do nothing to limit food choice.

And technology is and always will be important for production of a sufficient, affordable and safe food supply. ![]()

- Paul Beck

- Professor of Animal Science

- Southwest Research & Extension Center