Cattle feeders are said to have a little more “jingle” in their pockets and empty yard pens to fill, so producers throughout the country are hoping their 2010 calf crop blossoms over the summer months and bull selections prove themselves so they can see a little of that jingle filtering back into their own pockets.

The Spickler brothers, Nathan and Justin, of Glenfield, North Dakota, are keen on providing their seedstock clients with as much information as they can muster to help increase a cattleman’s profit.

Among data the Spicklers offer is carcass ultrasound EPDs. Since 2000 Spicklers have been ultrasounding their cattle to help select genetics that will gain and muscle effectively.

The Spicklers sell over 150 bulls each spring. While they include carcass characteristics in developing their genetics, they focus on a well-rounded animal and encourage their clients to consider the total package – phenotype, birth weight, maternal and other characteristics that will help you meet your marketing end point.

“Carcass data can be really valuable and we just see it as another piece of the puzzle when selecting genetics,” said Nathan Spickler. “We see more and more commercial producers using carcass data and we believe in providing the carcass ratios in our sale catalog so they can see how those bulls stack up against their peers.”

In addition to helping select their herd sires, commercial cattlemen can use ultrasound technology for determining their replacement heifers and farm feeders are able to improve their carcass yield and quality grades.

The Seven Blackfoot Ranch, with operations in both Montana and South Dakota, is a commercial cow-calf operation that has utilized carcass data for a number of years to select its bulls. Just recently it has begun to carcass ultrasound its heifers with the hopes of using the data to improve the quality of its calves, specifically the carcass quality.

“We are making an investment in the quality of our calves for the future and ultimately improving our reputation,” says Dave Solberg, owner of Seven Blackfoot, which feeds out all of its calves at the South Dakota ranch, located near Milesville. The cattle are then marketed on a grid system or through the local sale barn. “We are improving our overall quality, from the beef side to the heifer side. Knowing your bulls’ data is only half of making an intelligent decision for your operation.”

“We are making an investment in the quality of our calves for the future and ultimately improving our reputation,” says Dave Solberg, owner of Seven Blackfoot, which feeds out all of its calves at the South Dakota ranch, located near Milesville. The cattle are then marketed on a grid system or through the local sale barn. “We are improving our overall quality, from the beef side to the heifer side. Knowing your bulls’ data is only half of making an intelligent decision for your operation.”

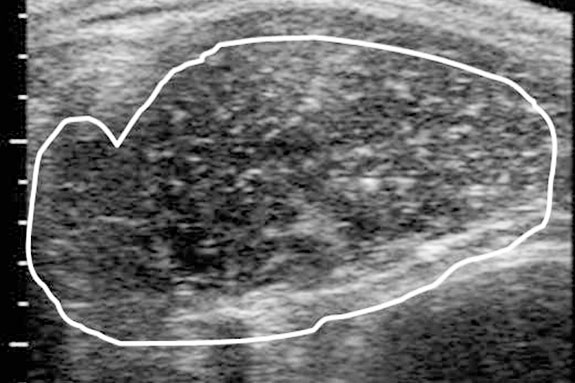

Each breed association has its own criteria for carcass data collection but most animals are scanned between 320 and 460 days of age. For commercial cattlemen that number range can fluctuate and they should contact an ultrasound technician to determine what would work best. The cattle have their hair clipped, vegetable oil is applied and then a 17-centimeter probe is used to capture an image of the rib fat thickness between the 12th and 13th rib, the percentage of intramuscular fat or marbling, along with a measurement of the ribeye in square inches and rump fat thickness.

Rump fat can be an indicator of early maturity and how well the animal can maintain body condition. Back fat thickness helps determine the potential yield grade – 1, 2, 3, 4 or 5 – while the intramuscular fat dictates if the carcass will be a quality grade prime, choice, select or standard.

Dan Hines of Old West Ultrasound in Martin, South Dakota, conducts the ultrasounds for Seven Blackfoot. He said approximately 5 to 10 percent of his clients are commercial cattle operations.

Data collected on calves reflect which cows are producing or not producing acceptable carcass merits in their offspring. Culling efforts can be conducted both on the cowherd and offspring. However, ultrasounding replacement heifers can speed up the process. That way producers don’t need to wait until year five or later to gather enough data on a cow to determine quality of her offspring. If the heifer scans poorly she can be promptly placed into a feedlot scenario without ever entering into the herd. Knowing a heifer’s carcass ability also enables cattlemen to breed them to bulls that will enhance and balance those traits.

“Commercial cattlemen are using the technology as a building block with which to build a better herd,” said Hines. “It allows them to better predict what their cattle can do in the herd or in the feedlot.”

For those who are backgrounding their cattle, they can better understand when an animal is ready to be harvested. The Spicklers also retain all their steers and cull heifers and use ultrasound data to help determine truckloads and when animals should be taken to slaughter.

“Visually we may think that the animal isn’t ready to be harvested, but the data could show back fat and ribeye measurements that would mean the animal is ready,” said Spickler. “It can be an advantage when making semi loads.”

If you are selling your cattle direct to a feedlot or through a sale barn, a reputation for cattle that are known to do well on the rail is very appealing to packers, and Hines says a customer return and premiums can be realized.

For more about carcass ultrasound technology, Hines recommends visiting the Centralized Ultrasound Processing Lab website, www.cuplab.com ![]()

Codi Vallery-Mills, Progressive Cattleman contributor

PHOTOS

TOP: Dan Hines of Old West Ultrasound conducts numerous carcass ultrasounds each year, as he did here for Seven Blackfoot Ranch located at Milesville, South Dakota. Photo courtesy of Sara Thissen.

BOTTOM: One of the measurements a carcass ultrasound can gather is the square inches of a ribeye. Photo courtesy of University of Minnesota.