All items containing steel were rationed, as were sugar, rubber and a lot of other commodities.

Today, there are many differences between wires, and purchasing has become more complicated. Choices in barbed wire include coating, twist type, material, gauge, type of barb and barb spacing.

In selecting net wire, you decide on class based on thickness of the galvanized coating, gauge, low-carbon or high-tensile, number of horizontal lines, types of knots, spacing between stay or vertical wires, height and length.

Wire coatings

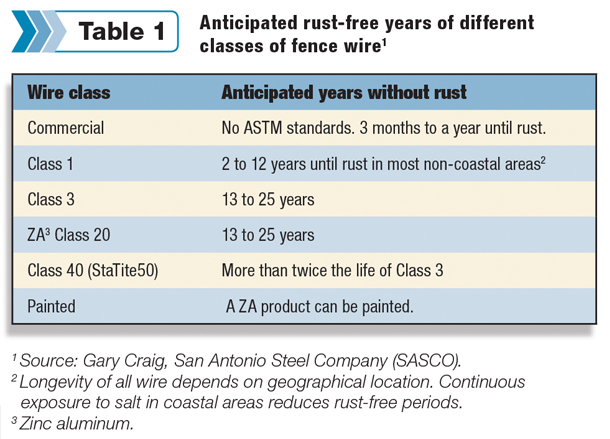

For protection against corrosion, fence wire is galvanized by dipping the manufactured product in hot molten zinc or zinc-aluminum. Thickness of the galvanized coating determines the class of wire and how long it is expected to last. Class has nothing to do with strength. All but one class of fence wire conform to ASTM standards.

ASTM International, formerly the American Society for Testing and Materials, was established in 1898 and sets standards for manufacturing that are critical to producing quality products. All government cost-share fencing projects reference meeting ASTM specifications.

Wire classes and their longevities are shown in Table 1. There is no stated amount of zinc on commercial class wire, whereas Class 1 has 0.28 ounces of zinc coating per square foot and Class 3 has 0.8 ounces per square foot.

Class 40 ZA has a combination of 95 percent zinc and 5 percent aluminum coating. Longevity of any class of wire depends on the environmental conditions of the area in which it is installed.

“You can’t tell the difference between commercial, Class 1 or Class 3 by looking at it,” says Gary Craig, marketing manager for San Antonio Steel Company (SASCO). “However, zinc-aluminum coatings have a grayish tint and are less shiny than wire with zinc coatings.”

San Antonio Steel Company is a wholesaler of foundation and agriculture fence products. Since 1965, they have supplied lumber yards, agricultural cooperatives and farm and ranch stores across Texas and in the neighboring states.

SASCO sells a variety of fence products manufactured by Bekaert, Keystone, Oklahoma Steel, Rangemaster, CMC Southern Post, W Silver and Pro Fencer.

Wire strength

Wire strength is an important purchasing decision and is expressed as break load, elongation and tensile strength.

Break load is the measured point at which wire breaks or pulls in two from an exerted force such as an impact from an animal. It is measured in pounds.

Elongation is how far a wire will stretch and decrease in diameter before it breaks. It is expressed as a percentage derived by dividing the original length of the test sample by the elongated length and then multiplying by 100.

Tensile strength is the force needed to pull 1 square inch of wire apart and is measured in pounds per square inch. For instance, high-tensile wire elongates 3 to 4 percent, and low-tensile wire elongates 10 to 12 percent.

“Wire strength is largely a factor of its carbon content,” says Harold Shipman, territory manager for Stay-Tuff Fence Mfg. Inc. “As carbon content increases, density of the wire also increases.

Low-carbon wire has a carbon content of approximately 0.1 percent, and high-tensile wire has approximately 0.28 percent carbon. Since low-carbon wire stretches, it requires more posts to keep it from sagging, making it less economical than high-tensile wire.”

Stay-Tuff Fence manufactures a range of high-tensile woven steel wire fence products suitable for most ranch, farm, highway, airport and light-security fencing requirements. The company also distributes a range of tools and accessories needed for fence installation.

Wire size and composition

Size of wire is expressed as gauge, which signifies its diameter. As the gauge number increases, the wire size decreases. For instance, diameter of 12-gauge wire is 0.081 inches, whereas diameter of 14-gauge wire is 0.064 inches.

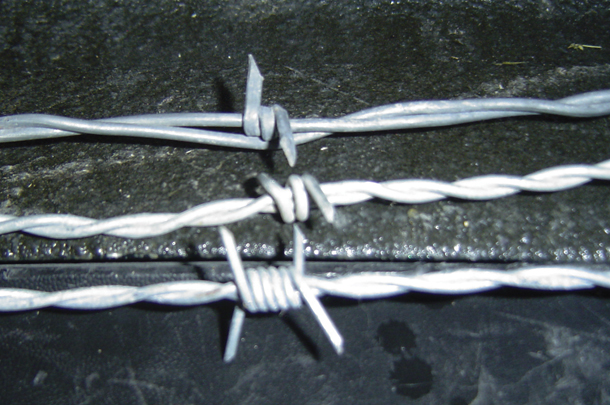

“Barbed wire is made with two strands of wire,” says Shipman. “The barbs are wrapped around a smooth wire, and then it is twisted together with a second smooth wire. Either flat wire or round wire is used to make the barbs. Choice of barb types is governed strictly by personal preference.”

“Both a two-point and a four-point barb are available,” says Craig. “The standard spacing of barbs is 4 inches or 5 inches. Six-inch spacing is used on some four-point barbed wires. For high-animal traffic areas, predator risks or security concerns, 3-inch spacing is recommended.

“Barbed wire is available in continuous-twist and reverse-twist designs. Continuous twist is commonly found in 12.5-gauge low-carbon varieties. Reverse twist is the new standard used by most manufacturers in their high-tensile barbed wire products. The reverse-twist designs alternate the direction of the two wires at the barbs to reduce sagging and better hold barbs in place.”

Woven wire is also called mesh wire, net wire and field wire. It is available in a variety of heights and configurations. A standard numbering system is used among manufacturers to designate their woven wire designs. An example Stay-Tuff product number is 2096-6-330. The first two digits are the number of horizontal wires.

The second two numbers are the height of the fence in inches. The middle number is the vertical stay wire spacing in inches, and the last three digits are the roll length. Product number 2096-6-330 has 20 horizontal wires, is 96 inches tall with 6-inch spacing between the stay wires, and the roll is 330 feet long.

The last three digits in wire product numbers designate different information among manufacturers. One of the woven wire products sold by SASCO is 842612S. This product has eight horizontal wires, and is 42 inches high with 6-inch spacing between the stay wires.

The last two digits in the SASCO product number designate the wire gauge, which is 12 in this product. In most cases, the last two digits refer to the gauge of interior wires only. Top and bottom wires are usually a heavier gauge. The “S” in the product number stands for the brand, StaTite50.

“The type of knot used in the manufacture of woven wire has an influence on fence performance,” says Craig. “A fixed knot utilizes solid vertical stay wires which increase vertical strength of the fence and allow for increased post spacing."

The knot is a separate piece of wire tightly wrapped around the line wire and stay wire. Fixed knot is very resistant to animal damage.

“S knot is found in products manufactured by Bekaert and Keystone Steel and Wire. This design uses a separate piece of wire to attach the line wire to the solid stay wire. The S knot is smooth to the touch and strong enough to resist animal impact."

“Hinge joint is found on both low-carbon and high-tensile fence products,” Craig continues. “This knot is common on agricultural fencing. The knot is formed by wrapping the vertical stay wire pieces around the line wire at each intersection. If made of high-tensile wire, this design can also absorb animal impact without damage. The hinge joint is the most economical choice.”

“Hinge joint is damaged with animal impact when made with low-carbon wire,” says Shipman. “Low-carbon wire stretches upon impact and has to be re-stretched or propped up with posts or stays.”

“A recent option in the United States is the forged knot utilized on woven wire manufactured in Australia,” adds Craig. “This knot is much stronger than conventional S knots because it is forged to the line and stay wires. It is smooth on both sides with the wire ends tucked in for livestock safety.”

Cost

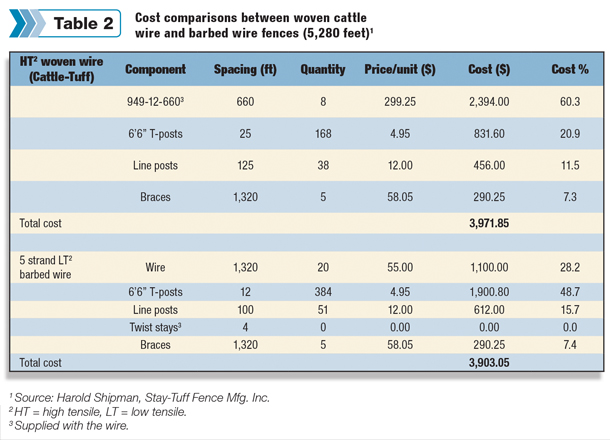

Like most ranch purchases, cost normally has a huge impact on product selection. Both Craig and Shipman see a movement away from barbed wire to woven wire, primarily because of the cost savings. The costs shown in Table 2 are for comparison only. In this particular case, a mile of the high-tensile woven wire fence costs only $75 more than a mile of low-tensile barbed wire fence.

The same amount or sometimes less labor is required to install woven wire than needed for barbed wire fence installation. Labor costs were not included in Table 2 for that reason. Woven wire is more expensive than barbed wire, but the savings is due to the requirement of less T-posts and line posts in high-tensile woven wire fences.

Influencing characteristics causing the shift to high-tensile woven wire include safety to livestock and wildlife, low maintenance, strength, longevity and resiliency. High-tensile wire normally snaps back into its original shape after being hit by an animal.

Almost every fence salesperson carries a video on their mobile phone of a deer hitting a high-tensile fence, bouncing back and then getting up and running off. If the wire didn’t give upon impact, the deer would have broken its neck.

Fence material selection can be a complicated process, so it is suggested that the purchaser work with a trusted supplier in designing a fence. Hopefully, this article supplies the information needed for asking the right questions. ![]()

Robert Fears is a freelance writer based in Texas.

PHOTO 1: Woven wire of fixed-knot design. Distance between vertical stay wires varies with type of animals to be contained. This fence is suitable for cattle and deer.

PHOTO 2: Top wire is 15½-gauge continuous twist, middle wire is 14-gauge reverse twist, and top wire is 12½-gauge reverse twist. Notice that top two wires have two barbs, and the bottom wire has four. Photos provided by Harold Shipman, courtesy of Stay-Tuff Fence Mfg. Inc.