The question I hear a lot is: “What is the cheapest way to cover hay?” First, we should evaluate our needs for hay coverage and our objectives for marketing or using the stored hay.

The value of hay, storage time, environmental conditions, accessibility and interactions among those factors affect the economics and type of hay storage. Hay tarps are a versatile and relatively inexpensive option to conserve hay value.

Investments in hay barns and pad structures need a 10- to 20-year period to yield beneficial returns. Other factors to consider are the market flexibility and how long the hay will be stored each year and in what seasons.

Environmental factors

Producers in a climate with high precipitation, relative humidity and temperature will have higher-moisture hay and higher storage losses than a climate that is drier and cooler. The loss of dry matter (DM) or mass of hay appears to be nearly proportional to the length of storage.

Reported losses in alfalfa hay range from 0.5 to 1.5 percent DM per month of storage in drier climates and 1 to 3 percent DM per month in wetter climates.

It is well-known that storing hay inside a building results in the least DM losses, 1 to 5 percent. It is important to reduce the exposure of hay bales to moisture from all dimensions.

Bales will absorb moisture from the soil if left outside on bare soil, which can reduce the amount of tonnage from 5 to 20 percent during a nine-month storage in the Midwest and 15 to 50 percent DM loss for 12 to 18 months storage. Even when covered by plastic tarps, contact with moist soil increases the DM loss compared to bales not in contact with soil.

Hay sheds and barns

Hay sheds are permanent structures which may have zero to three sides covered. Hay barns are totally enclosed. Hay barns and sheds are the most effective at reducing storage losses to about 5 percent and set the standards by which other methods are compared.

Hay storage buildings also provide benefits of security against theft and can be used for other purposes such as machinery storage during a portion of the year. Although property tax will likely also increase, the overall value of a farm should increase with the addition of a hay barn.

In humid environments, reduced losses from hay shed storage can justify construction costs within a few years. Hay sheds have a high initial cost and annual capital costs of about $4 per ton on a 20-year amortization, and usually a small property tax payment.

Hay shed costs amortized over a 30- to 40-year period are competitive with tarping costs. However, annual labor time and costs for shed storage are minimal compared to tarping or wrapping hay. Producers should calculate the anticipated construction cost, then compare the cost to the estimated cost of hay lost due to weathering.

Tarps

Numerous types of coverings are available. Plastic sheeting should be at least 6 mils thick. Vinyl and polyethylene tarps are more expensive but reusable and easier to secure.

Polyethylene tarps have the advantage of allowing moisture to move out of the hay, which reduces condensation under the tarp.

Cheap tarps with eyelets to attach ropes will not last long. A good tarp will have 1-foot-by-2-inch boards about 3 feet long in a double-backed edge of the polyethylene tarp, which is double-stitched and has ropes attached in two places on the board.

Labor to install a “cheap” tarp may be more expensive than installing a good tarp. Commercial tarping businesses also lease, install and remove tarps. One company quoted $3.14 per bale for flat-top stack bales (4 foot by 4 foot by 8 inches) to lease the tarps, which included installation.

Tarps should be tied down snugly and sides set out from stack edge so water does not run down the stack. Cost of hay covers, not including labor, can range from less than $2 to more than $7 per ton, depending on type of cover and size of stack.

Covers require continual attention for repairing tears and re-securing tie-downs, especially during periods of high winds.

Pads

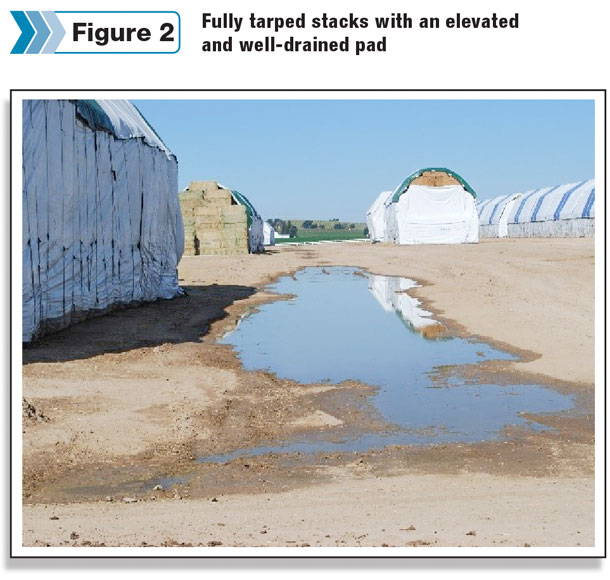

A crushed rock pad with geotextile fabric is the best method of separating the hay from soil moisture. Even in arid climates, the stack pads and barns need to be constructed at a higher elevation with adequate drainage. Concrete can allow for water to wick up through the floor and produce moldy hay on the bottom.

What’s the economic return from various bale storage systems?

Hay tarps and pads are low-capital-cost investments for hay storage. Tarps are variable in the initial quality, construction design and the care an operation gives them. A good-quality tarp can last four years if it is kept tight and stored out of the sun and weather during the off season.

An “inexpensive” tarp may not even last one season. Enclosed and ventilated hay barns are high-capital-cost but lower labor costs and have some worker safety benefits. Be safety-conscious when installing tarps.

Marketability and usability of hay conserved with the best methods are maximized with proper storage. Forage quality influences the price, as does handling and feeding convenience.

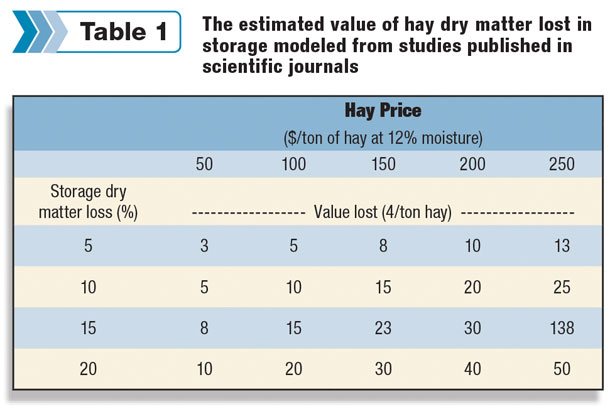

Table 1 shows the hay value lost as a function of dry matter loss during storage and the original hay value. For example, hay worth $200 per ton, losing 15 percent dry matter, the value lost is $30 per ton of the original hay.

A case study comparing forage quality on covered and non-covered hay

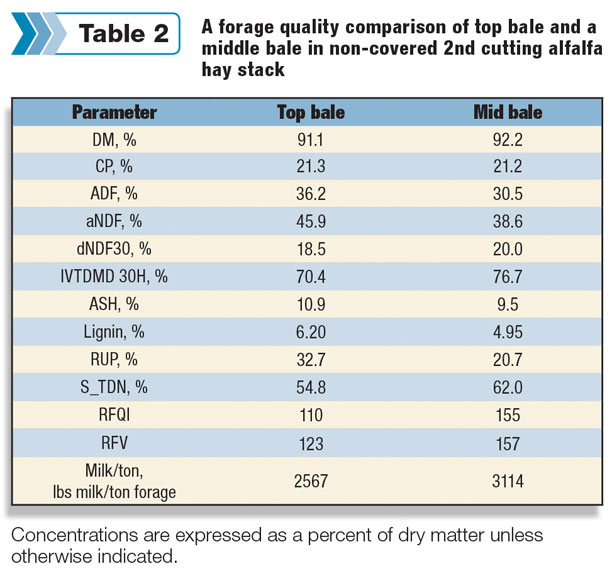

The acid detergent fiber (ADF), neutral detergent fiber (aNDF), lignin and rumen-undegradable crude protein (RUP) concentrations appear higher in the top bale compared to the middle bale (Table 2); however, only one comparison was made.

The calculated parameters of summative total digestible nutrients (sTDN), relative forage quality for legumes (RFQl), relative feed value (RFV) and milk per ton of forage, neutral detergent fiber digestibility at 30 hours (NDFd30), in vitro total dry matter digestibility (IVTDMd 48H) and NDFd at 48 hours (NDFd48, as percent of NDF) were lower in the top bale than the middle bale.

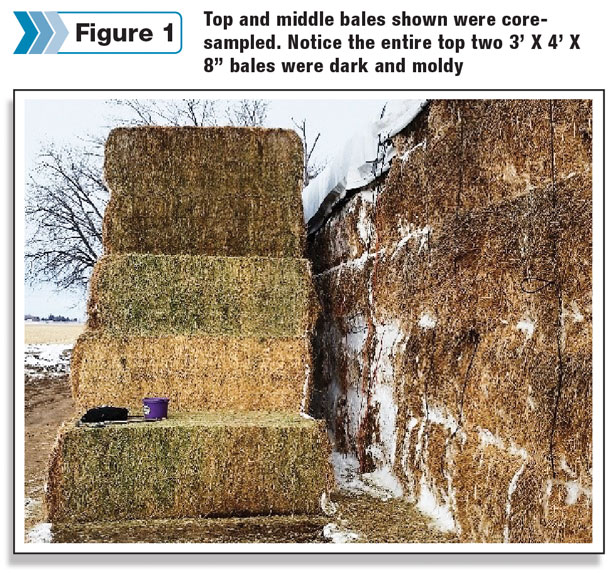

Although statistical analysis is not appropriate, there is an obvious deterioration of the forage quality of the hay. The top bale was dark-brown to black color with mold evident (Figure 1).

Beef cows refused to eat the majority of top bales. Moldy hay should never be force-fed to livestock.

The top bales might have a value of one-half that of the middle bale based on forage quality test. However, the top two bales have considerable mold, of which the animals will refuse a large portion.

Uncovered stacks in a year with ample supplies and slow demand sometimes lead to unmarketable hay – no one wants it at any price.

In this stack of five bales high with some damage on the bottom bales and the top two layers moldy, about half of the tonnage is of marginal value.

If the market for the middle bales was $150 per ton and the market for the top bales was $75 per ton, the average value of the stack is about $112 per ton. A stack of 100 tons that had the potential value of $15,000 versus the damaged value of $7,500.

Costs of hay storage options

The size and construction materials used are the biggest factors for building costs. The important question is: “What loss of dry matter, forage quality and marketability can I sustain before I can afford to cover my stack?”

The crushed rock pad with tarp covering is probably the most cost-effective system for six-month storage. For longer storage periods, hay for export or horse markets, or environments with a short window for getting a tarp covering on, a hay shed or barn may be the best long-term investment.

Marketability for export demands a fully tarped stack or hay shed with at least two sides to reduce bleaching.

Hay storage recommendations

Evaluate your hay storage management plan. Use a storage method that fits your marketing or feed usage conditions, and evaluate the cost and benefits of temporary versus more permanent facilities.

The best situation for marketing hay is to sell the hay in the field at its best quality and pass the storage and management costs on to the buyer. If a grower wants to speculate on a rising hay market, one must consider the added storage costs of dry matter and quality loss – and these are considerable.

For a producer that feeds his own hay, covering the stack will still pay if you consider the cost of wasted moldy hay and the risk of feeding too much moldy hay to your livestock. Consider all factors before deciding on purchasing hay tarps or sheds because although cost per ton is important, so is labor, equipment, accident risk and flexibility in access and marketing. ![]()

References omitted due to space but are available upon request. Click here to email an editor.

-

Glenn Shewmaker

- Extension Forage Specialist

- University of Idaho – Kimberly R&E Center

- Email Glenn Shewmaker