Efficient and profitable confined animal feeding operation (CAFO) managers must address vital key points to maximize limited time and resources. As a CAFO manager, consider the following points as best management practices for handling manure: soils, pens, mud, dust and odor control.This article provides a framework important to managers regarding administrative decisions and will also highlight the science of how to manage manure most efficiently.

Two constants when feeding cattle include supplying fresh, palatable feed to ensure cattle gain weight and efficient manure management.

The materials leaving a feedlot must balance materials coming into a feedlot. Cattle, feed and water come into the operation. As a result, the manure byproduct must be managed to ensure a balanced operation.

The concept of environmental sustainability requires that manure and pen runoff is utilized by operations so it does not compromise surface and groundwater quality.

Manure management can pose some challenges in the form of cattle gain and losses. Potential losses from poor manure management include deep pens that cause increased energy loss by cattle; and seepage into the ground from pen surfaces, under manure stockpiles and from runoff catch basins. There is also a potential for surface runoff from manure stockpiles and cropland applications.

Manure management and plant need

Manure contains many essential nutrients for effective crop production including nitrogen (N), phosphorus (P), potassium (K), sulphur (S) and several trace elements that are necessary nutrients in crop production.

Beef manure is not necessarily a balanced fertilizer, and therefore manure applied at a rate to satisfy one crop nutrient need may result in overapplication of other nutrients.

Some of these nutrients can be bound up, and in some instances, may be unavailable for plant uptake. It may take several years for these nutrients to become available to plants.

The contribution of this residual release must be accounted for in determining application rates, particularly on land receiving yearly applications of manure.

It is very important to monitor both manure and soil nutrient status on a regular basis to detect actual build-up of soil nutrients. Three factors that influence the nutrient availability to plants following manure applications are:

- Manure handling, storage and application management

- Time between storage and field application

- Environmental factors including temperature, moisture and wind speed

Hauling manure to the field within seven days of excretion will provide the highest nitrogen content to the crop.

Composting manure within seven days of excretion will produce the next-most-valuable manure product in terms of nitrogen content. Handling manure by cleaning the pen once a year contributes to the greatest nitrogen loss from manure.

Salt build-up

Many water supplies are naturally high in salts. Excess sodium, in relation to calcium and magnesium in the soil, can result in physical degradation of the soil structure.

Care should be taken when determining application rates where the water source and the soils are known to be high in salts.

Many people associate salt with sodium chloride or common table salt. In reality, the salts that affect both surface water and groundwater frequently are a combination of sodium, calcium, potassium, magnesium, chlorides, nitrates, sulfates, bicarbonates and carbonates. These mineral salts originate from the earth’s crust.

These salts also result from natural weathering, in which small amounts of rock and other mineral deposits are dissolved into the soil over time and redistributed by water.

Over time this slow weathering causes salts to accumulate in both surface and underground water.

The surface runoff of these dissolved salts is what gives the salt content to our oceans and lakes. Fertilizers and organic amendments also add salts to the soil.

As soils become more saline, plants are unable to draw as much water from the soil. This is because the plant roots contain varying concentrations of salt ions that create a natural flow of water from the soil into the plant roots.

As the level of salinity in the soil nears that of the roots, water becomes less able to enter the root.

In fact, when the soil salinity levels are high enough, the water in the roots is pulled back into the soil. The plants become unable to take in enough water to grow.

Each plant species naturally contains varying levels of root salts. This is why some plants can continue to thrive when others have died when soils build up salts.

Manure management considerations

Continued applications of manure will increase the organic matter content of the soil.

Decomposition of manure in the soil has a long-term effect on improving soil structure and water-holding capacity.

Optimal management of feedlot manure can form a sustainable link between livestock production and sustaining a fertile soil resource.

Pen considerations

Proper construction and maintenance of the feeding pen surface is important for animal health, welfare and productivity. A smooth, firm surface with a 2 to 4 percent slope will drain well.

In densely populated pens with less than 250 to 300 square feet per head, the trampling action of cattle and the accumulation of manure and urine will cause four distinct layers to develop in a pen.

Starting at the bottom, these four layers are: the initial pen surface, a compacted soil manure layer, a gleyed hardpan layer and the base layer. Proper management of these layers will control runoff, prevent seepage of nutrients down into the ground and provide a clean, comfortable surface for cattle.

The action of the cattle hooves mixes manure and urine into the soil. Chemicals in the manure and urine change the soil’s physical and chemical properties.

High sodium levels cause soil particles to disperse and reduce water infiltration. Organic gels, or slimes, form under low-oxygen (anaerobic) conditions, further reducing infiltration and seepage.

Manure pack

The manure pack is the total accumulation of manure and bedding in the pen. This pack acts like a giant sponge, absorbing rain and snowmelt. It can hold 1 to 1.5 inches of rainfall.

When rain falls on a feedlot pen with built-up manure pack, the pack absorbs the water until it is saturated. The hardpan layer, or layer three, prevents the percolation of water downward.

When the manure pack is saturated, runoff begins and the excess water runs to the lowest point of the pen.

Typically, there is anywhere from immediate runoff to a 24-hour delay after a storm before pen runoff begins. Additional storage is created in the pens by the depressions created by the cattle’s hooves. Pen slope and manure pack depth will affect onset of runoff.

The infiltration and hydrology of feedlot pen soils is similar to the behavior of claylike soils. These soils have a high runoff and erosion potential.

Feedlot soils should be similar. However, the manure layer and the microdepressions created by the cattle’s hooves provide much more moisture storage than a conventional soil.

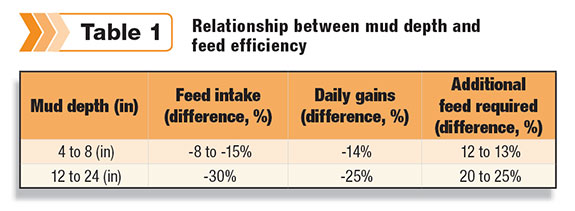

Cost of mud and poor drainage

Muddy pens are costly. Feed intake goes down. Daily animal gains decrease, and the total feed required for feeding cattle increases as well.

Another way to evaluate cost is that every four muddy days adds one additional day to the total time spent in the feedlot.

Optimizing dust and odor control

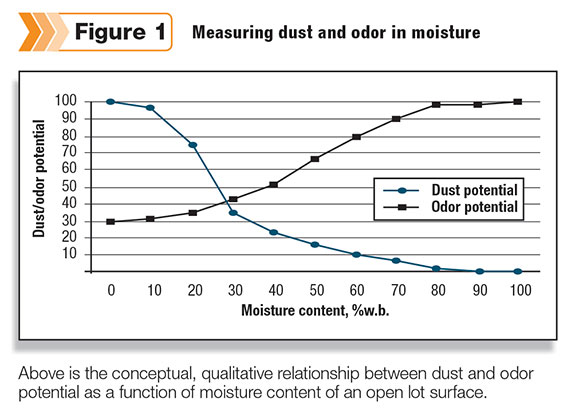

Dust and odor are the two primary air-quality contaminants from feedlots. Emission of these two contaminants is controlled primarily by the moisture content of the feedlot surface.

Dust is the predominant problem at low moisture content, and odor is prevalent when there is high moisture content. Minimizing both dust and odor by moisture management alone is impossible.

Researchers found that when the moisture content of the open-lot surface is between 25 percent and 40 percent, both dust and odor potential are at manageable levels.

In the optimum moisture range of 25 percent to 40 percent on a wet basis, other properties such as manure depth, bulk density and texture become the most important determinants of dust and odor potential.

The most important principle of odor control is to avoid anaerobic conditions by keeping:

- Manure and other organic materials as dry as practical

- Manure storages and surfaces exposed to oxygen

- Open-lot surfaces hard, smooth, and free of loose manure

In summary, the vital key points when managing the CAFO include manure, soils, pens, cost of mud, and dust and odor.

There are two constant inputs and outputs. Cattle come to the feedlot to be cared for, fed and managed. The byproducts can help CAFOs experience additional financial success.

Management of manure and the crop nutrients contained within the material need to be handled correctly and efficiently to maximize cattle growth and to keep the lot at peak performance for maximum positive animal health.

The use of manure can enhance crop growth. Understanding how manure interacts within the soil helps managers make better decisions and minimize the negative effects on the surrounding land. It will also maximize profits of the cattle feeding operation. ![]()

Jonathan Hogge

Jefferson County Extension Office University of Idaho