While these data sources provided a snapshot of quality defect incidence in the industry, none directly measured the adoption of production practices consistent with BQA guidelines prior to the feedyard segment.

Therefore, a 43-question survey was developed to assess BQA-related production practices used by U.S. cattle producers to serve as a benchmark and provide a foundation for future educational initiatives.

Access was provided to cattle producers online and at industry events during Phase III of the NBQA-2011, which was led by researchers at Colorado State University and Texas A&M University. Surveys were completed by 3,755 cattle producers from 45 states, of which 74.8 percent were commercial cow-calf operators.

Ensuring beef safety, which is the cornerstone of BQA, is something cattle producers work hard to do.

Injections and medicines

Over 95 percent of survey respondents always or usually verified that proper withdrawal times for animal health products were followed. However, 2 percent of respondents acknowledged that they never verified their adherence to proper withdrawal time – which highlights an opportunity for improvement within the industry.

Overall, 78.3 percent of respondents used individual ear tags to keep track of cattle receiving animal health products. It is imperative to food safety and consumer confidence that producers ensure cattle that have not yet met their drug withdrawal period never enter the marketplace.

Another core BQA principle involves establishment of a working relationship with a veterinarian by cattle producers. Nine out of 10 survey respondents said they had such a partnership, often referred to as a veterinary-client-patient relationship (VCPR)

. However, only 31.3 percent of all respondents had a written protocol for health treatments. Improper use of animal health products can result in end-product quality defect and safety issues, including violative drug residues and inferior carcass traits due to poor animal health status and performance.

More widespread use of written protocols and records for cattle health management is warranted, particularly as consumers seek more information about the beef production process.

Injection-site management has long been a cornerstone in the BQA program and its trainings. In this survey, 84.2 percent of respondents said their preferred route of administration was subcutaneously (SubQ or under the skin), which is the recommended option within BQA. Placing injections in front of the shoulder in the neck area is another key BQA principle, and over 87 percent of respondents said this was their preferred injection location.

Such high rates of adherence to BQA guidelines are commendable, particularly since injections were overwhelmingly given intramuscularly in the rump when BQA began in the 1980s.

Moving the preferred injection site location to the neck region and changing route of administration to SubQ has greatly improved end-product quality by avoiding significant damage to high-value cuts in the round and sirloin regions of the carcass.

Low-stress handling

Low-stress cattle handling is a priority among cattle producers and a component of BQA trainings. Survey respondents indicated that the “use of good stockmanship and animal handling skills” was their primary method of intentionally influencing quality in the cattle they produced.

In fact, over 98 percent of respondents did not use an electric prod as their primary driving tool when working cattle, and 50 percent didn’t use one at all. Among those that used an electric prod, 86 percent used it on less than 10 percent of their cattle.

Low-stress animal handling helps reduce end-product quality defects and losses due to bruising, dark cutting beef and stress-induced poor animal health performance.

An impressive 85 percent of commercial cow-calf operators that completed the survey had heard of BQA, of which 69.3 percent had attended a BQA training or completed one online.

Among those that completed a BQA training, 78.1 percent said a certificate of completion was provided. Thus, based on the total number of respondents, approximately 42.6 percent of cow-calf operators indicated they were BQA certified.

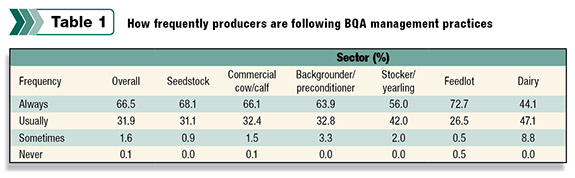

Of commercial cow-calf producers that attended a BQA-type training, 98.5 percent stated that they followed best management practices consistent with BQA on their operation (Table 1).

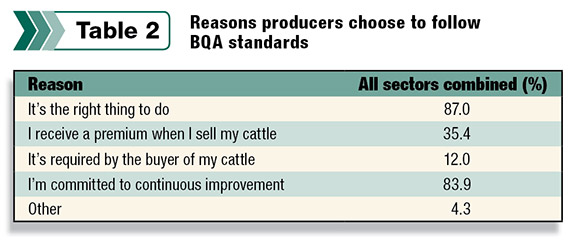

When asked why they choose to follow such practices, 87.0 percent said because it was the right thing to do, and 83.9 percent indicated they were committed to continuous improvement on their operation (Table 2).

These results suggest that a financial reward tied to BQA certification is not essential for producers to participate in the BQA program.

In conclusion, producers must consciously utilize appropriate animal handling, care and health management practices to meet consumer demands. Cattle producers recognize that using BQA-oriented management practices is the right thing to do, and BQA is a tool to help improve their cattle.

The BQA program has changed production practices among cattle producers. However, continued educational efforts should continue to be a high priority within the industry to enhance the rate of adoption of BQA principles, including more widespread use of record-keeping.

Continued development of on-ranch or on-farm educational tools regarding BQA will further enhance the adoption of BQA principles at the grass-roots level. ![]()

Editor’s note: This article includes a brief summary of information contained in the final report from Phase III of the NBQA-11. Visit the website for the report.

Jason Ahola

Assistant Professor Beef Production Systems

Colorado State University